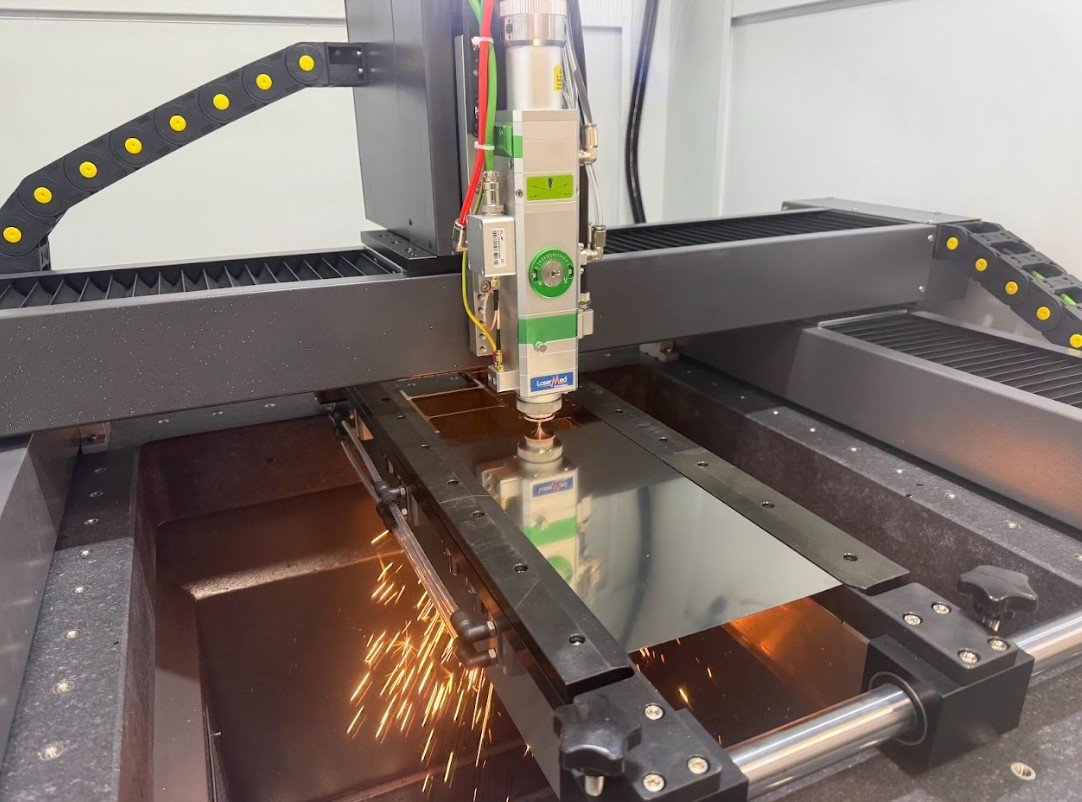

FLATBED LASER CUTTING

This capability allows us to accurately cut flat metal sheets—including medical-grade materials—with tight tolerances and consistent quality.

How it works.

Flatbed laser cutting uses a focused, high-powered beam to cut precise 2D shapes from flat sheet metal.

Our system delivers clean, burr-free edges with tight tolerances—ideal for both simple and complex designs.

The non-contact process minimizes material stress and enables fast turnaround for prototypes and production.

Materials.

Our flatbed laser system supports a wide range of metals commonly used in medical, aerospace, and industrial applications.

Nitinol

Stainless steel

Other medical-grade alloys

What we offer to our clients.

By integrating flatbed laser cutting into our service offerings, LaserMed provides greater flexibility and faster delivery for flat metal components. This capability allows us to:

Cut materials up to 1/8” thick with a maximum sheet size of 4 square feet.

Reduce lead times for prototypes and production parts

Provide consistent, high-quality results across short and long production runs